In the Part 1 of this Series on Gas Lift History and Basic Well Parameters, an attempt was made

to bring into focus the primary “state of affairs” of Gas Lift operations in the USA.

Part 2 will discuss basic Gas Lift well casing and tubing components, and their operational

function, as well as Choke Flow relationships in Gas Lift wells.

In the First Section II.A, Energy and Mass Balance relationships will be used to compute

flowing pressure gradients, (dP/dL) (psi/ft) for injected casing gas ((dP/dL)g), and for further

documents addressing this subject, multiphase flow in the tubing ((dP/dL)mp).

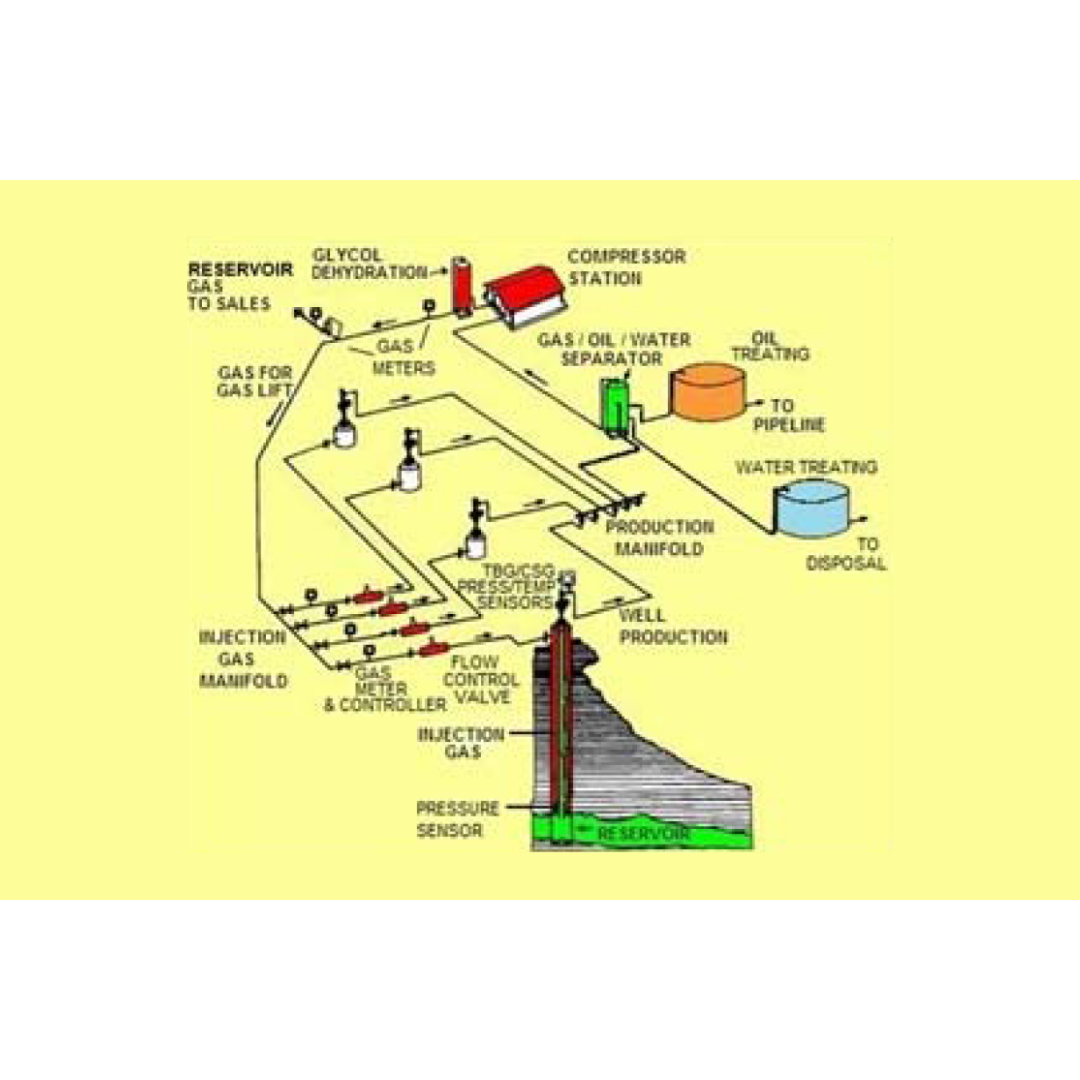

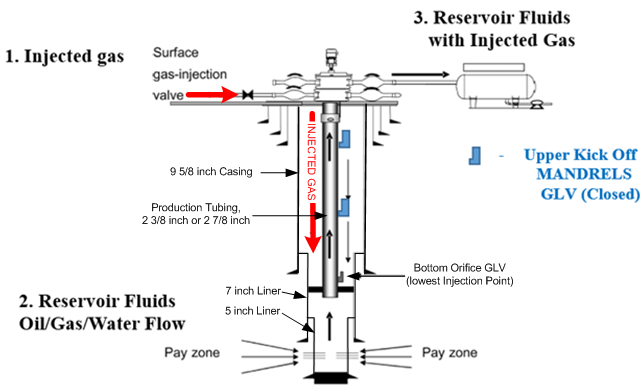

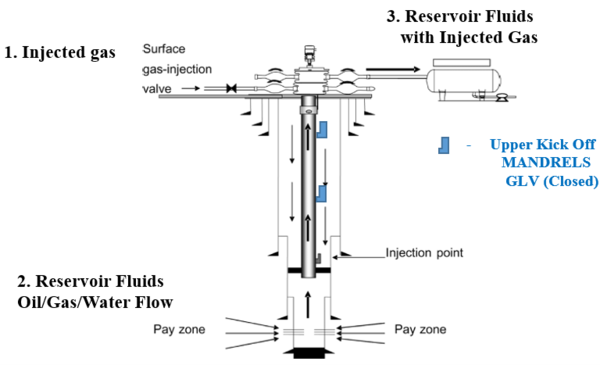

Section II.B will address gas injected at surface into the annular space between production

casing and tubing. The injection gas travels down the annular space on its way to either a

“kickoff “gas-lift” valve located in a tubing MANDREL with an Injection Pressure Operated

gas lift valve (IPO), or to the bottom Orifice GLV. Calculations will be performed to determine

injected gas annular flow vs. pressure loss related to the 9 5/8” casing and either the 2 3/8”, or

2 7/8” production tubing. The flow is then considered in the annular space between the 7” liner

and either the 2 3/8’’, or 2 7/8’’ production tubing. Casing gas flow does not encounter the 5”

liner. Physical dimensions for these selections will be addressed.

Section II.C presents the basic, single phase gas flow performance characterization related to

CHOKE FLOW in the Gas Lift Valve. Once a valve has been fitted with a choke (orifice) size,

the flow performance of a choke will follow the mass, and energy balance relationships related

to isentropic gas expansion. This flowing condition for the choke MUST be selected in its

transitional, sub-critical flow region so that additional changes to injection gas flowrates may

be made if called for. It is essential to design the final Orifice GLV so that operation near, or in

the Critical Regime (Sonic Flow) is avoided.

A numerical example will be presented to illustrate the direct application Casing / Liner Gas

injection data with the corresponding IPR Tubing Gas Lift Valve with installed CHOKE

dimensions.

[Keep reading]